Dimpled jacket tanks

Labbe Process Equipment designs and manufactures tailor made dimpled jacket tanks within its 15 000 m² workshop. Thanks to its latest laser welding machine, Labbe ensures a complete manufacturing without any subcontracting activities in order to guarantee the best quality and the shortest delivery time.

The vessels are made in:

– stainless steel (304l, 316l, 316ti, 321, 310S stainless steel),

– Duplex (U45N, U35N stainless steel),

– Super duplex (UB6, 904l stainless steel)

– Nickel alloy (c22, C276 Hastelloy) for the very corrosive products.

For some application, Labbe Process Equipment manufactures Inconel, Monel or Titanium vessels.

Labbe Process Equipment can propose all types of finishing (polishing, electropolishing) for all kind of application: food reactor, chemical reactor, pharmaceutical reactor …

Labbe answers to all industrial requests offering you dimpled jacket tanks according to your regulations:

ATEX, SEVESO, FDA, and ANIA

Labbe answers to all industrial requests offering you dimpled jacket tanks according to your regulations:

ATEX, SEVESO, FDA, and ANIA

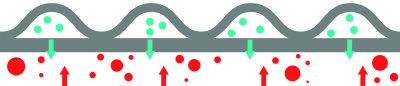

Laser welded vessels (dimpled jacket tanks) are the most reliable solution in a lot of fields of activities: food industry (particularly in dairies), chemistry, pharmacy …

This technology is recognized in all the world for its reliability adapted for heating or cooling.

The laser welding technology used by Labbe for vessels ensures a high quality. This technology is totally automated, and enables a cost reduction of a laborious classical operation.

Thanks to our laser welding machines, the heat generated is perfectly controlled and the realized tanks do not require any post-treatment.

Labbe laser welded plates can be used with all types of refrigerants: glycol, Ammonia, R404A, R134A, CO2… Our heat exchangers are perfectly adapted to all following applications :

Milk tanks

Ferments culture

Ice cream

Crystallization

Pasteurization