Compalex® : welded plates heat exchangers

With the Internet spreading linke wildfire and reaching every part of our daily life, more and more traffic is directed to websites in search for information.

Conditions of use

– Monophase, condensation or evaporation use

– Maximum pressure 40 bar (contact us for superior pressure)

– Maximum temperature 400°C

– Cleaning possibility on the two circuits

– Welds inspection possibility

Construction codes Compalex®

– CODAP, EN13445, ASME ou AD-MERKBLATT

– CE marking according to European norms (DESP 2014/68/UE)

Materials

Manufactured in accordance with the construction codes in force as well as the TEMA standard:

– Stainless Steel 304L, 316L, 316Ti, 321, 310S

– Duplex U45N, U35N

– Uranus B6

– Nickel Alloys C22, C276, C2000

– Incoloy

Labbe has a wide range of grades of stainless steel as well as nickel alloys.

Welded plates heat exchangers Compalex® manufacturing

We calculate and design our heat exchangers based on your needs and constraints.Welded plates heat exchangers proposed by Labbe Process Equipment are laser spot welded and have high thermal performances with optimized product flow velocity and minimized pressure drop.

Applications: • Liquid / Liquid • Condensation • Evaporation • Gas / Gas • Gas / Liquid • Air / Water

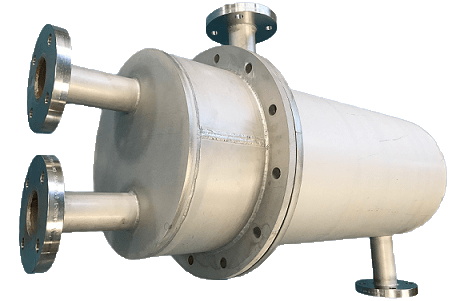

Cylindrical shell

The Compalex® heat exchanger is available with a cylindrical shell. It is a heat exchanger with a bundle of welded plates, removable or not.

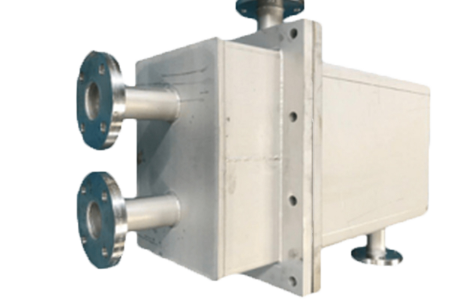

Cubic frame

The Compalex® heat exchanger is available with a cubic frame. It is a heat exchanger with a bundle of welded plates, removable or not.