Labbe, manufacturer of flash evaporator and liquid-vapor separator

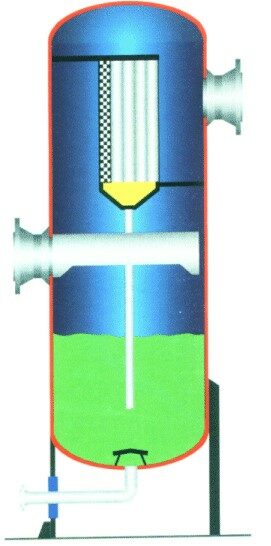

Flash evaporator and liquid-vapor separator are the simplest separation equipment used in chemical industry. Liquid-vapor separators are only used for phase separation, whereas flash evaporators allow for a partial or total component separation.

A correct design and sizing of such a separator is required to obtain an optimal separation.

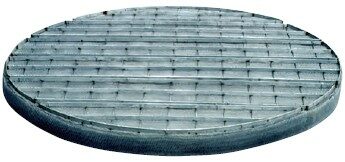

Liquid-vapor separators use gravity to isolate the vapor from the liquid. A demister can be added to reduce the overall size of the separator and increase the separation efficiency.

A flash evaporator works on the same principle, but instead of a two-phase feed, a pressurized single-phase superheated liquid feed is flashed inside the separator, generating the two phase with a different composition each.

Types of evaporators and separators

With more than 70 years of experience, Labbe masters all steps in manufacturing of flash evaporator and liquid/vapor separator. This, from sizing to the construction, without subcontracting, for all types of equipments:

Flash evaporator

– distilled water generator

– brine evaporator

– multiple stage evaporator

Liquid vapor separator

– with or without demister

– single or two-phase liquid

Internals of flash evaporators

With its factory adjacent to the design office and with a stock of over 1000 tons of materials, Labbe offers an unmatched manufacturing time from the initial request to the delivery, with state-of-the-art quality control.

Accurate demister characteristics and flows analysis are used to design the flash evaporator or liquid-vapor separator.

The feed inlets and demister are chosen from Labbe wide range of internals to obtain the best performances/size ratio and separation efficiency.

Labbe Process Equipment provides all the internals associated:

inlet devices, demister, vortex breaker, control valve