Labbe, your supplier of separators, gas scrubbers and demisters

Mist elimination specialist, Labbe offers you a large range of standard or customized solutions for news or existing installations.

Labbe manufactures and produces separators and gas scrubbers integrating demisters. Indeed, the mist plays a key role in a lot of industrials processes. It allows an important cost saving thanks to the recovery of a part of the product, improving the efficiency of the installation at the same time. In addition, it contributes to the reduction of wear and the reduction of equipment breakdown.

In order to obtain good results, droplets separation has to be efficient so perfectly adapted to the process. Consequently, a good control of the process together with the physical aspects of the mist elimination is necessary.

What is an efficient mist?

An efficient droplet separation:

protects the installation

saves energy

recovers a part of the product

increases the efficiency

ensures higher flowrates

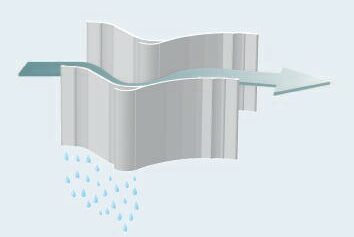

Vertical flow

Horizontal flow

Dropplet separation : Mist élimination

The droplets are the result of impurities in the gaseous phase creating condensation during cooling phase, except when it’s the consequence of high flowrate.

The droplets extraction conveyed by a gas flow is made by a demister. An efficient execution needs the expertise of Labbe.

Labbe reinforces its skills since many years and collaborate with its clients to offer the best technology adapted to the process.

The characteristics of Labbe demisters are always tested and updated following the process development and the operation conditions.

Also, the fundamental characteristics of installations are evaluated thanks to a large database and a powerful design software.

The cooling of a gas creates the apparition of condensates. Except if they are eliminated, these condensates can create a lot of damages in the downstream equipment. Moreover, without moisture elimination conveyed by the gas, the gas compression before the next step of the process would require more energy.

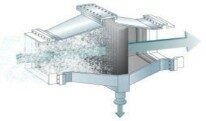

The evaporation separation

Thermal separation of products thanks to evaporation is a usual process in the industry of transformation. The objective of extraction changes from one activity to another, but in all cases it’s about producing more by reducing energy consumption and of raw material.

Those processes of industrial evaporation are generally made in several stages: evaporation of the solvent in several stages, the product phase becoming more and more viscous and concentrate. This system increases the risk of downstream equipment breakdowns in case of priming.

Moreover, every lost droplets represent a loss of raw material and energy. A demisters play a key role in this type of installation: he protects the equipment and reduces the loss of product.

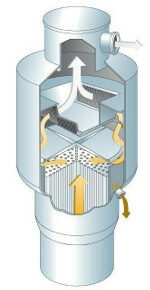

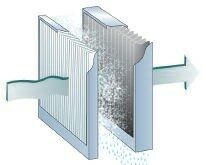

Differents droplets eliminator for petrochemistry

Horizontal demister

Vertical demister

Trellis demister

Spark plug filter